Chance Meeting Turns Into 70 Year Success

Where there are steel and other metals in industry, there is welding. It is an essential part of the construction of all types of structures and large machinery, and has been since the dawn of the industrial age.

For not quite that long – more like 70 years, to be exact – Barry-Hamel Equipment Ltd. has existed to service the welding requirements of big corporations and individuals alike who need the latest in equipment, and the support to back it up.

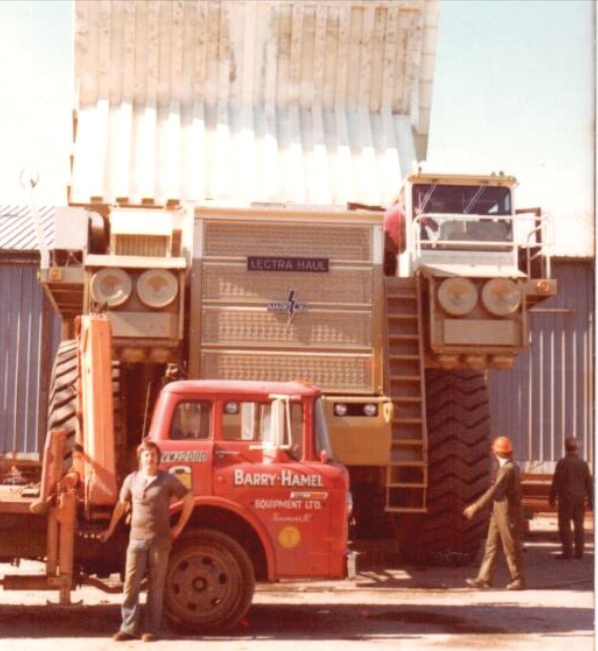

The company, which began operations in the Vancouver area in 1954 and continues today in Coquitlam in the shadow of one of the biggest welding projects in British Columbia, the new Port Mann Bridge, is the country’s premier welding sales and service provider. With a full range of machines for sale or rent, the ability to provide all levels of service for them, a complete range of the gases needed for the different processes, and a warehouse full of all the accessories and consumable items used in the trade, Barry-Hamel Equipment Ltd. is a one-stop shop for the professional welder.

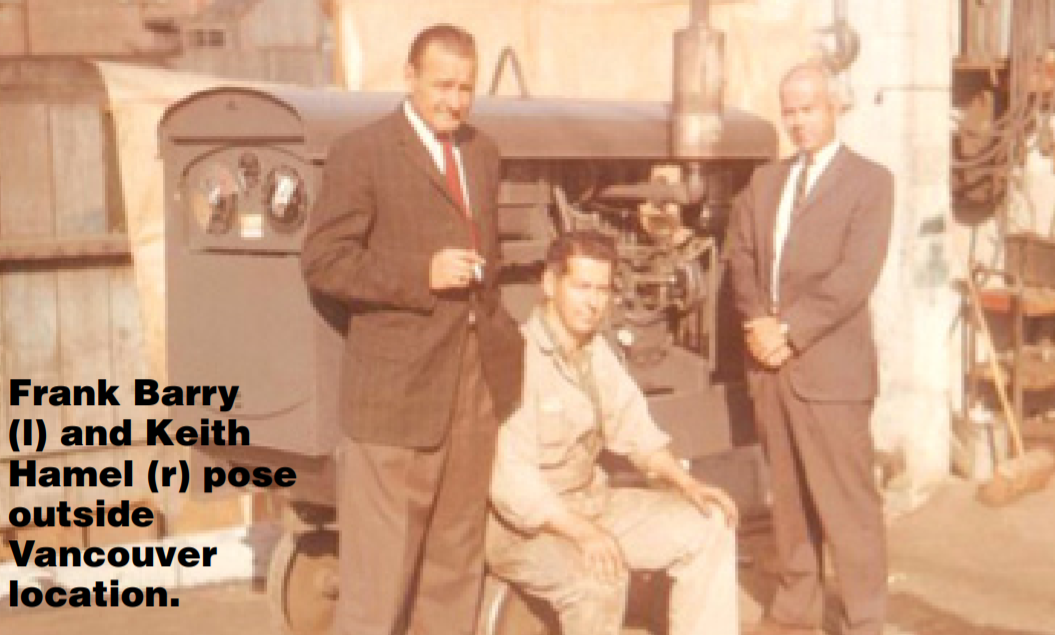

Like many business success stories, Barry-Hamel began life through a series of fortuitous occurrences and meetings. Frank Barry arrived in Vancouver from Ontario with the proverbial ten cents in his pocket, and as an outgoing 19 year-old go-getter, met lots of people who helped him make more connections. Eventually, after working for the owner of two Esso gas stations near downtown Vancouver at 1st & Burrard and Cornwall & Yew (now a restaurant), he took over the business and got to know a lot of his customers.

One, a Mr. Hamel, told him that a welding machine company called Lincoln Electric was looking for a dealer. He sold the two Esso franchises, and went into partnership with Mr. Hamel in 1954. Barry-Hamel Equipment Ltd. was born.

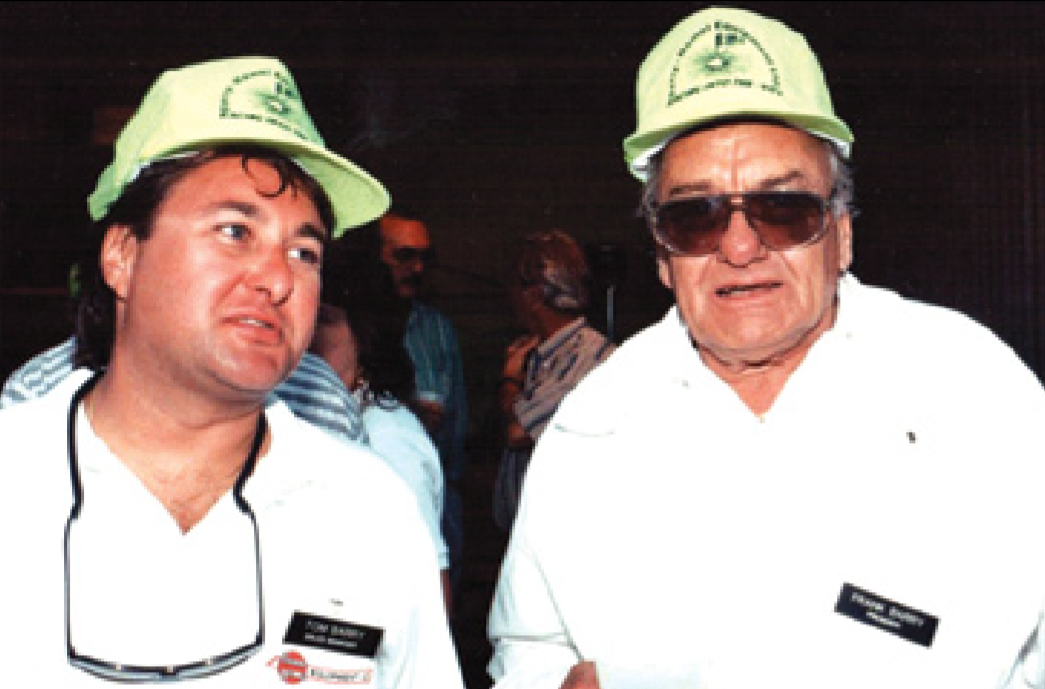

The company did well, but seemingly not as well as expected as far as the ‘bottom line’ in the financial statements went. It turns out that the company accountant was bilking them of a lot of money. Following the crooked cipher’s self-inflicted death, Barry bought out Hamel, and the company has been in Barry family control since that day in 1963. Frank Barry retired in 1985, and the business was taken over by his son Tom Barry, who runs it to this day.

Tom took some time recently to tell us the Barry-Hamel Equipment Ltd. story, and following his description of being part of the social scene and travelling with Team Penske during the heyday of North American open-wheel auto racing in the 1990s, he warmed to the subject of welding and the company’s growth as a major supplier.

“When the company was started, all we did was distribute Lincoln Electric welding machines and consumables like welding rod. Then, my Dad started a welding equipment rental business, and we wanted to become a repair depot, too, but Lincoln Electric had a rule that a distributor could not be a repair depot as well. We wanted to be able to fix our rental units, so we opened B&H Welder Repair. Same address, different phone number. It took them eight years to catch on,” he laughs. “When we moved into this building in 1994, we got sick and tired of everything involved with running two separate companies, so we folded B&H Welder Repair. Nobody cares anymore, and the rules have changed since.”

Barry continues the story. “When I was 21, I moved from the shop into inside sales, and found that we had to suggest people went elsewhere for accessories like welder’s helmets, gloves and other safety items. So I said to myself, what are we doing? So, we started selling accessories here. Now, we had new equipment rentals, repairs, consumables and accessories for welding. My competitors were doing the same stuff, but some of them were doing industrial gases, too, so 15 years ago, we hired an expert in the field who came from an industrial gas company to set up that side of the business. We became an Air Liquide distributor, and it’s been a good line for us and has been growing steadily.”

The story of how Barry came to realize that the sale of industrial gases made good business sense is a fascinating one. “I’ll tell you what convinced us to go with gases. One of the biggest gas distributors in the world is Praxair based in Europe, and we went for a tour of their plant. We kept seeing Swastikas on the cylinders, so we asked them, what’s with all the Swastikas on the cylinders? We were told that the cylinders keep showing up back at Praxair to be repainted or disposed of and that they last over one-hundred years. These had seen use in Germany in World War Two. So wait a minute... after doing the cost to purchase versus the monthly rental the math was quite simple…we were in! If you can get a welding machine to last 15 or 20 years you are doing really well. And you’ll be spending a lot on upkeep.”

Clearly, Barry-Hamel Equipment Ltd. are the experts in welding – and only welding. “When you walk into this building, it is all about welding,” Barry says. “There is nothing else going on here. You walk through the shop, past the Technicians working on welders, right into the showroom, and there is the sales advisor behind the counter ready to help you. There are times I’ve thought of starting a new division, because we sell equipment that makes things come together. We could get into glue and solvents and plastic welding, but we stick with steel and arc welding. We are looking at opening a branch on Vancouver Island, as a customer we have is involved in a billion-dollar job over there, and he wants us there.”

Of course, much has changed over the course of several decades, in terms of technology and design of the machinery. “Welders are like most machines,” Barry says. “They are getting smaller, more powerful, and costing less. For what you are getting, it’s costing way less. An electric welder that used to weigh 800 pounds can now be put in a big lunch box. So, it’s definitely gone that route. And the technology....it’s all computerized now, of course. You can even track welding arc/hours by satellite. You can tell when the welding machine isn’t working, which leads into duty cycle management, and job performance measurement.” So, the welding function is now more management-friendly, as it can be measured in terms of cost per hour or job.

The actual welding, the point where the sparks are flying that is the signature visual effect most people associate with it, has also changed, with new processes and applications. “There used to be just electric arc welding. Now there is resistance welding, pressure welding, water cutting, plasma cutting, laser cutting, even robotics.” Barry-Hamel Equipment Ltd. and its suppliers are completely on top of all these new developments in the trade.

To keep up with all that is new in welding takes a team of motivated and talented staff, and BarryHamel Equipment Ltd. boasts the most experienced people in the industry, both in sales and service. Tom Barry explains how this is not easy to accomplish. “We try to get welders to come in and work with us, but they won’t do it. They make too much money. It’s usually through word of mouth, although sometimes with an ad. Sometimes we get guys walking in off the street looking for a job. Those kinds of guys, we want; at least he’s out there looking. We have to train all our own people as it’s really, really hard to find the right people in our industry, and people try to seduce them away all the time.

“People like working here,” he continues. “We try to make it as nice as possible, to keep my people happy. People come to us, because it’s a nice place to work. It’s a team here, and everybody gets involved in major decisions.” In our short guided tour of the Barry-Hamel Equipment Ltd. facility, it was very evident that the atmosphere is one of teamwork and mutual support. “One of the guys wanted to get a stock car team together. We let them use our truck and some space in the back of the shop. It’s all about team building.” It’s also clear that Barry, being of a certain age, is looking to the future of Barry-Hamel Equipment Ltd. “My goals are to get the people here to take over this company, to get young people into the business.”

The future of welding itself is, like most older technical activities, coming to terms with new technologies and possibilities. “Years ago,” Barry explains, “Lincoln had us watch the movie about the nuclear plant in the States that was melting down., which was caused by a faulty weld. In the movie Alien, as they were running away from the monster, they closed a door and had this big gun in their hands, and went zap-zap and welded the door shut. The reason they wanted us to watch that is, that’s where it’s going. We’re almost there now, almost there to the handheld machine that will do a weld. It’s getting really close, certainly as far as the size of it goes. Welding is getting to the point where everyone will have something in their house to do it. It’s going to be a very simple process. It’ll be like 3D printing. You don’t believe it, but it works.”

Barry-Hamel Equipment Ltd. General Manager, Steve Curr, believes that “we are in an energy-saving era now, and the new technology makes machines much more efficient. The techniques and procedures used have become a lot more stringent.” And that sounds much like the situation facing the automotive industry.

With the mention of 3D printing, Barry doesn’t discount the possibility of Barry-Hamel Equipment Ltd. getting involved with it, in some way. “I’ve thought of it. The future we can see is that we aren’t going to stock parts and ship them out; we are going to make them right here. We’d love to see fifty 3D printers in a row downstairs, spitting out parts. They will be huge for any industry like welding that has consumables. We’ll be doing it, if we are still around.”

There should be little doubt of that, given all the possible major projects on the horizon. “We’re good for 20 years here. We’ve got the pipelines nobody wants to talk about. We’ve got a billion-dollar dam rebuild project in Campbell River. There are the military boats in North Vancouver. There’s lots of action going on up north. Our main customers right now would be ship building, petrochemical, and believe it or not, forestry. Some of our biggest customers are the pulp mills. Even though people say forestry is dead… it’s not.”

There are no other welding suppliers in North America that do it all like Barry-Hamel Equipment Ltd. And it all began 60 years ago with a chance meeting at a gas station....

|

Proud Supplier to Barry-Hamel Equipment Ltd |

Lincoln Electric is never far from any discussion of the formation and growth of BarryHamel Equipment Ltd., and for that matter, the growth of the welding industry itself.

After all, the company was formed in 1895 and pioneered many of the welding innovations taken for granted today. The Lincoln brothers made their first welding set in 1909. In 1916, The Lincoln Electric Company of Canada was incorporated to distribute the U.S.-made products.

Through the 1920s and ‘30s, Lincoln Electric created a new type of electrode and welding flux in order to make welds both stronger and more ductile, more closely matching the characteristics of the steel used.

Like most industrial companies, the beginning of America’s involvement in World War II resulted in a huge demand for welding equipment, in order to build the ships and other armaments needed to fight the war. Lincoln Electric’s business grew dramatically, and this growth continued until the recession of the early-1980s, when it fell some 40 percent.

To counter that decline, the company embarked on a plan of foreign expansion, which led to it being the world’s dominant producer of welding equipment and supplies. Since the turn of the century, Lincoln has acquired well over a dozen foreign companies in the welding and equipment field, including in the world’s fastest-growing welding market, China.

Today, it is fair to say that Lincoln Electric sells more welding equipment in Canada than any other company. A quick look at their website, www.linconelectric.coméen-ca, shows literally dozens of machines across the many different types of welding processes, far beyond the scope of this article to describe. But if you are a welder, there will be something there for your area of expertise.

Of course, Lincoln Electric played a key role in the formation of Barry-Hamel Equipment Ltd. 70 years ago, and according to Tom Barry, “Barry-Hamel Equipment Ltd. often sells more Lincoln Electric product than everybody else in B.C. combined. We are so associated with Lincoln that there are times people call us thinking that we are them!”

So, just what makes Lincoln welders better than the others? Tom Barry knows, and it has to do with both experience, and the same ‘team’ approach that he takes with his own company. “They’ve been building them for over a hundred years. And they were the first ones to do it. But how they run their company is a big reason. They are a profit-sharing organization. Every single person who works for them wants their equipment to be successful. If they send out a welder, and it comes back to the factory under warranty, they come in at night, on their own time, to fix it. All the equipment in the Lincoln factory is fixed on their own time. I don’t think Lincoln has had a layoff in the history of the company.”

Of course, Lincoln makes more than just machines, as welding takes up a lot of consumable items like welding rod and wire. So, it’s no surprise that of all Lincoln’s products, Barry-Hamel Equipment Ltd. sells more consumables than anything. “We sell so much welding rod and wire, it’s mind blowing. We supply lots of schools for their shops, like BCIT and the Pipe Trade College. Pulp and paper and petrochemical companies are right up there amongst our biggest customers.”

Put simply, Barry-Hamel Equipment Ltd. is Lincoln Electric Canada’s biggest dealer, and Lincoln is Barry-Hamel Equipment Ltd.’s biggest supplier. “Without Lincoln Electric, Barry-Hamel Equipment Ltd. and the Barry family wouldn’t be where we are today. We go hand-in-hand.”

After 70 years of making each other’s companies successful, this business relationship is a strong one.

Variety of Suppliers Give Customers Power of Choice

There is no doubt that Barry-Hamel Equipment Ltd. is associated closely with Lincoln Electric welding products, but that doesn’t mean that the company doesn’t carry other excellent equipment for the welding professional.

Chief among the other brands available at Barry-Hamel Equipment Ltd. is the Miller Electric line of welding machines and supplies, and Tom Barry appreciates the company’s focus on its top priority: people – the same focus he has at Barry-Hamel. “We love dealing with Miller,” he says. “They are great people to deal with.”

Miller Electric Mfg. Co., with headquarters in Appleton, Wisconsin, manufactures arc welding and cutting equipment designed for manufacturing, fabrication, construction, aviation, motorsports, education, agriculture and marine applications.

Miller does business through an ever-increasing focus on customers’ welding challenges in specific market segments and applications and, ultimately, their complete satisfaction. Miller knows that customers in these industries don’t just buy welders; they want welding system solutions.

The Miller story began in 1929 when Neils Miller recognized the need for a small, affordable arc welder that would operate on the type of electricity readily available in rural Wisconsin, where he lived. Miller Electric Mfg. Co. was incorporated in 1935. The next year, Al Mulder, Miller’s sole engineer, invented the world’s first high frequency-stabilized AC industrial welder, which put Miller on the map, so to speak.

The innovation has continued unabated over the ensuing decades, and today, Miller has 1,400 employees working in product-focused factories, known as business units, which optimize production flow and improve quality.

One simple fact showcases the power of Miller’s organization: while the number of production workers is about the same as it was 15 years ago, today’s workforce produces twice as many welders. Few companies in the world can boast a 100 percent production increase, much less do it with a workforce that has an average tenure of 19+ years and a turnover of less than 2 percent.

Without specialized gases, there would not be welding as we know it, and Barry-Hamel Equipment Ltd. is proud to have Air Liquide as its primary supplier of gas products.

Air Liquide is one of the world’s largest and most experienced suppliers of gases for all industries, including oxygen, nitrogen, hydrogen and rare gases. Based in Paris, France, the company has operations in 80 countries, with its Canadian headquarters in Montreal. Operations there began in 1911, and today, there are offices in several Canadian cities.

Air Liquide has been closely associated with welding since the early days. Several key steps were made during the 1920s: Air Liquide Canada began to manufacture fluxcoated electrodes – the first enterprise to do so in North-America – and promoted bronze welding for the repair of cast iron. The company offered free welding instructions at all branches and published “The Welding Review” for its customers.

In the 1940s, the company opened Canada’s first welding and gas applications research laboratory, as well as a state-of-the-art welding electrode plant, and the world’s largest oxygen plant.

Introduced in 1999, ALTOP revolutionized the welding industry. It is the first industrial cylinder with a fully integrated valve and regulator, which provide instant gas flow at the desired pressure.

Needless to say, Air Liquide has been at the forefront of new technologies for the welding industry, working closely with the hardware manufacturers to bring welding to the advanced position it now enjoys

Barry-Hamel stocks many other names in welding supplies – Hobart Welding Equipment, Victor Technologies Torches and Regulators, Noramco Electrical, SCN Industrial, Walter Surface Technologies and Lenco Canada to name but a few – ensuring that the professional welder can find everything he or she is looking for, all under one roof.

Barry-Hamel Equipment is truly the one-stop shop for everything to do with welding, with the knowledgeable staff to back it all up.